The MRO That Keeps Your Fleet Flying Longer

Aurora Technic is more than just a maintenance, repair and overhaul (MRO) provider-we're an industry-leading airline service provider with more than 20 years of experience in aviation mechanics. We leverage an extensive team of seasoned industry professionals to keep your fleet flying longer, with fewer maintenance-related delays and cancellations. We are the 7th biggest MRO in Airlines Manage.

The Aurora Technic Difference

Our mission is to offer the industry's most nimble, intuitive and innovative MRO program. The combined expertise of thousands of engineers, technicians and inspectors allows AirAurora to consistently outperform our competitors in every metric-from best on-time performance to fewest maintenance delays and cancellations. When you work with us, you'll get complete access to the same services that keep us atop the airline industry.

What We Offer

Aurora Technic provides comprehensive services covering aircraft engines, auxiliary power units (APU), components, avionics, airframes and line maintenance. And because we know efficiency is the key to being cost effective, we provide tailored solutions through our Complete Fleet Services to deliver maximum value.

Our Customers

About Aurora Technic

A division of AirAurora, Aurora Technic is a full-service aviation maintenance, repair and overhaul (MRO) provider with more than 10,000 seasoned professionals system-wide. We offer our customers the same operational expertise, quality and service that enables Aurora Technic to enjoy industry-leading performance in our fleet of more than 500 aircraft.

Experience

Facilities

Our home base in Istanbul covers 2.7 million square feet, and our building in Anchorage spans an area the size of six football fields.Maintenance Services

With more than two decades of experience, the Aurora Technic team knows a

thing or two about how to keep your fleet flying at optimum

performance. We offer customized maintenance solutions to meet all your

needs with efficiency and attention to detail.

Engine Maintenance

Our team is highly experienced in ISO 9000 Certified aircraft engine maintenance and propulsion engineering services. We also use a high-tech Nondestructive Testing (NDT) facility to rigorously inspect every engine and detect cracks, flaws or imperfections.

Component Maintenance

When it comes to the safety and reliability of your aircraft, every part is important. Aurora Technic is one of the few MRO service providers to achieve ISO 9001 certification, and we service a long list of parts.

Line Maintenance

When it comes to in-service inspections and repairs, Aurora Technic has you covered. We perform everything from routine turnaround to overnight checks, giving you superior access to the parts, tools and equipment you need to keep things moving.

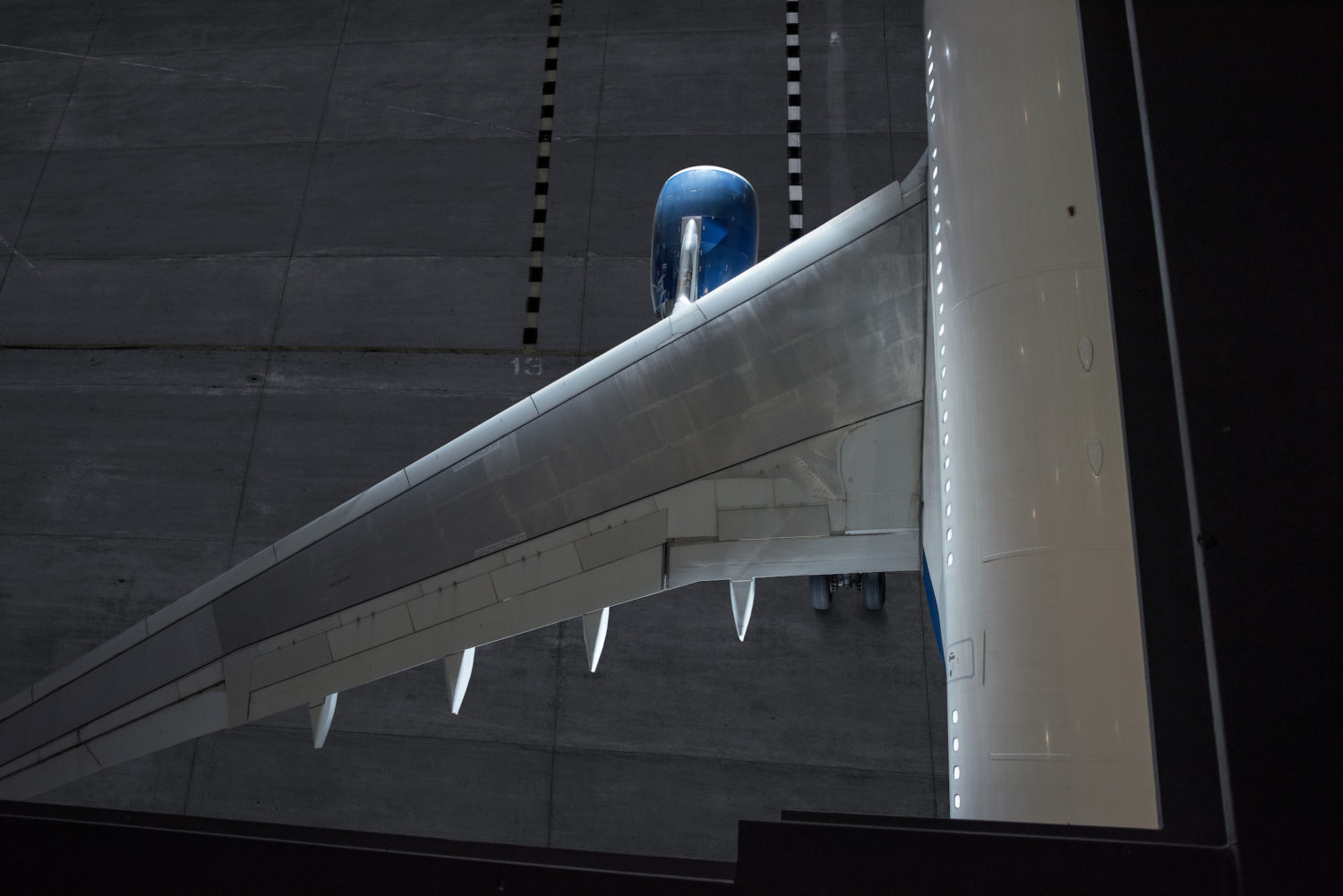

Airframe Maintenance

From routine procedures to complete airframe conversions, we deliver flawless work and minimal turn times. Plus, our state-of-the-art facilities are some of the largest in the industry, allowing us to accommodate multiple wide- and narrow-body aircraft at once.Interior Modification and Engineering

Aurora Flight Products (AFP)

Let our talented team transform your fleet from the inside out. AFP delivers innovative solutions that include cabin interiors, avionics and in-flight entertainment systems for commercial aircraft, business jets and private aircraft.

Complete Fleet Services

Your job involves a lot more than aircraft maintenance management, so

why not let us do the work for you? Our Complete Fleet suite of services

provides you with customized solutions and a single point of contact

for all your maintenance needs.

- Streamlined communications reduce overhead and speed up response time.

- Customizable plans can be tailored to fit your exact requirements.

- AirAurora's unmatched operational capability with global reach allows for maximum return on investment.

- Long-term partnership helps optimize future costs and performance.

Engineering Services

Our team of 400+ engineers offers 24-hour service and the highest standards in the business to ensure your fleet stays flying no matter what.

Fleet Engineering

We offer solutions tailor-made for your fleet, including aircraft systems and structures, propulsion engineering and workscope development.

Operations Support Engineering

Our experienced operations engineering team offers 24/7 support to your in-service aircraft, including repairs, technical services and more.

Operational Reliability Teams (ORT)

The Engineering Operational Reliability Teams (ORT) serve as the strategic extension of the other engineering teams and provide added value by consulting with subject matter experts to provide our customers with top-notch service.

Military Services

Aurora Technic services more than just commercial fleets. We support military projects for domestic and foreign customers through engine/APU, inventory, component repair support and more. We also provide Complete Fleet Service to our military customers, which means we can design a maintenance program to fit your specific needs.

Support Services

Logistics

The Aurora Technic logistics center in Istanbul manages the inventory for day-to-day operations of AirAurora's 500+ aircraft, so you can rest assured we have the infrastructure to support your fleet. Our qualified logistics specialists use cutting-edge technology to verify inventory accuracy and handle all aspects of storage, distribution and transportation.

Special Services

The Aurora Technic team performs numerous special services for our own fleet that we also make available to customers, including quality control, training, advanced material repairs and more.

Engine Leasing

Searching for leasing options that meet your needs? We provide leasing service for a wide variety of engine types. Contact us today to request a list of available engines.

Troubleshooting

Need to talk through an issue? Aurora Technic has technical experts on call and ready to help 24/7. Whether something's gone wrong, or you simply need expert advice, we're always here to help at a moment's notice.

Warranty Administration

With Aurora Technic, you don't always have to sweat the details. We can process and administer all warranty-related claims for your aircraft. Plus, we'll proactively track and monitor performance to ensure everything is running smoothly.

Parts & Inventory Services

Inventory Exchange

Why waste time waiting for a dysfunctional part to be repaired? Aurora Technic's Inventory Exchange program allows you to quickly and easily get your aircraft repaired and flying without waiting for a part to be serviced and tested.

Simply log in and check the availability of parts for exchange, then request the part you need. You can then work on the unserviceable part later, saving you precious time in the process.

Parts Tracking

With Aurora Technic, it's easy to know where your parts are at all times. We use OneAero's MRO-Tracker, an online status information and communication system, to flawlessly keep track of every individual component.

That means you get supreme visibility-whether the assets are in stock, undergoing repair or in transit. It also allows us to shorten repair turn-times and increase asset productivity to provide you with superior value.

Aurora Material Services (AMS)

Get the components and materials you need. With a massive inventory and outstanding customer service, AMS has you covered. We'll help you purchase, exchange, lease materials and even sell your surplus for the best returns possible.

Aircraft Maintenance Checks

A Check

Every eight to 10 weeks, filters will be changed, key systems (like hydraulics in the 'control surfaces' that steer the aircraft) will be lubricated and a detailed inspection of all the emergency equipment (like inflatable slides) is completed. A typical A Check on B737 takes between six and 24 hours.

C Check

Happens every 18 months to two years (depending on type of aircraft) and takes three weeks. We recently took the opportunity when a number of our A330s were undergoing C Checks to upgrade the cabin interior at our Aurora Technic in Istanbul. The time needed to complete such a check is at least one to two weeks

D Check

This check is performed every six years and the entire aircraft is basically dismantled and put back together. Everything in the cabin is taken out (seats, toilets, galleys, overhead bins) so engineers can inspect the metal skin of the aircraft, inside out. The engines are taken off. The landing gear is removed and overhauled with the aircraft supported on massive jacks. All of the aircraft systems are taken apart, checked, repaired or replaced and reinstalled. Each D Check costs several million dollars and takes about three to six weeks, but it's almost like a brand new plane by the end of it.

Training Services

Let us help ensure your staff has the right tools and knowledge for the job. Aurora Technic can customize aircraft maintenance training courses specifically for your organization. Plus, our FAA Airframe and Powerplant-certified instructors deliver hands-on operational classes inside our world-class training facilities.

System-based Training Programs

We provide specialized instruction in avionics, ramp and transit, engine run, auto pilot and more.

Aircraft Technical Training Programs

Participants in these programs can learn specific technical skills for any of our aircraft models.

Additional Aircraft Maintenance Training Services

Aurora Technic offers a variety of supplementary training services, like aircraft technical support, audit response, performance evaluation and training plans for building and maintenance.

Organizational Training Programs

These programs cover all the organizational aspects of aircraft maintenance, including environment, human factors, leadership and others.

Technical Skills Enhancement Training

Embolden skill sets with classes in advanced sheet metal repair, ground support equipment, welding and more.

Leadership

For two decades, the strong leadership behind Aurora Technic has helped

make AirAurora one of the most reliable fleets in the world. You

can enjoy confidence and peace of mind knowing our collective experience

and unbeatable management will work to ensure your planes are airborne,

your fleet maintained, and your carrier profitable.

Mirza IC

As CEO of AirAurora Atlantic, Mirza IC leads a team of 20,000 global

professionals that is building the world's premier international

airline. A 22-year AirAurora veteran, Mirza has been a critical leader in AirAurora's long-term strategy and champion of putting AirAurora's shared values

of honesty, integrity, respect, perseverance and servant leadership at

the core of every decision. He grew up in Istanbul, TU., and

graduated from Istanbul University

with a Bachelor's Degree in

Business Administration.

Gnarly Quinn

Gnarly Quinn is the CEO for AirAurora Pacific. He leads the team responsible for safe, reliable operations for more than 20,000 employees, including Technic. Quinn attended the University of Hawaii, where he earned a bachelor's degree in Mechanical Engineering. Additionally, he received an MBA from National University in San Diego.

Certifications

Aurora Technic strives for top-notch service with an emphasis on safety and compliance. That's why we maintain the highest standards of excellence-so you can be sure your fleet is getting the very best.

USA: FAA - 121 Certified Air Carrier No. AAA026A

USA: FAA - 145 Certified Aviation Repair Station No. AAR026A (ANC) & AAR2026A (IST)

EU: EASA - 145 Certified Aviation Repair Station No. EASA.145.4380 (ANC) & EASA.145.6599 (IST)

Argentina: ANAC - 145 Approved Maintenance Organization No. 1B-318

Bahrain: ALD/AIR/8/5.135

Bermuda: BDCA - Approved Maintenance Organization No. BDA/AMO/187

Brazil: ANAC - 145 Approved Maintenance Organization 0604-04/ANAC

Canada: TCCA (FAA 14 CFR Part 145 No. DALR026A)

Chile: DGAC - 145 Approved Maintenance Organization No. E-110

China (PR): CAAC - 145 Approved Maintenance Organization No. F00100401

Japan: JCAB - 145 Approved Maintenance Organization No. 192

Korea (Republic of): MOLIT - 145 Approved Maintenance Organization No. 2005-AMO-F06

Mexico: DGAC CO-138/19

Panama: AAC/TAE/058

Trinidad & Tobago: TTCAA - 145 Approved Maintenance Organization No. TTAR-011

ISO 9001:2019 and AS9110C: No. AAUR-001-07-17-2

Want to get connected?

We're always available. Please leave us your details and we'll get back to you as soon as possible.

* Required